Functional Safety Services

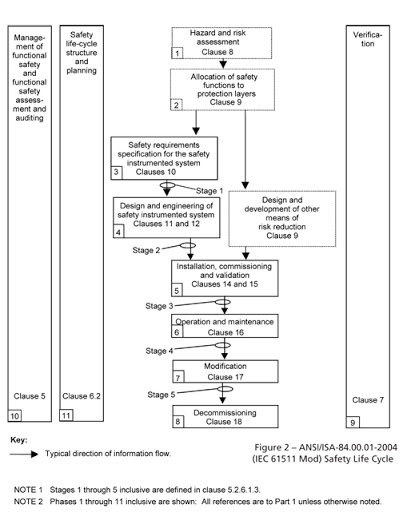

Compliance to the international Standards such as IEC 61508 and IEC 61511 are imperative to meeting the Functional Safety requirements for many processes and have formed part of the quality management systems of many companies. Provision of Functional Safety Services in line with the Phases and Activities detailed in the Safety Life-cycle is an area in which our consultants have demonstrated to have vast experience and expertise.

Functional Safety services can be categorised into 3 main areas:

- Management of Functional Safety for control and minimisation of Systematic Errors.

- Reliability Assessment in terms of Random Hardware Failures.

- Architectural Assessment and requirements for Hardware Fault Tolerance.

Input of expert consultancy services in Front End Engineering or Detailed Design stages are key in achieving Functional Safety. Support in procurement, design and implementation of Safety Instrumented Systems are imperative in meeting the safety requirements of a project. Engineering Safety can support you on all your functional safety requirements.

The following is an extraction from IEC 61508, which represents the simplified Safety Life Cycle.

Our Functional Safety Services Are

Technical Safety Services

Alarm Management, Flow Assurance, Plan Optimisation, RAMS and RCM are just a few of the Engineering Safety Consultancy services we specialise in for the process sector. Globally we are approached at various stages of engineering design to support the various goals and requirements of projects.

Over the years we have grown quite a reputation in the provision of high quality engineering consultancy services which is supported by our extensive list of clients.

Our Technical Safety Services Are

Inspection & Testing (NDT)

Non-Destructive Testing (NDT) or Non-Destructive Evaluation (NDE) terminologies are often used interchangeably within the inspection and testing industry. These methods are used to describe measurements which are more qualitative in nature such as locating the defect and measuring the severity of the identified problem (i.e. size, shape and orientation).

The field of NDT is fairly broad and in many cases a combination of several NDT methods are required to complete an inspection procedure, hence understanding the application of each testing principle is critical, especially prior to initiation of test. Our team of experts, can help identify the most applicable test principles for various application requirements in order to protect against the potential catastrophic events whilst improving efficiently and reducing downtime.

Engineering safety has a dedicated and fully qualified ISO 9712 NDT level 3 team covering the following inspection disciplines:

- Radiography

- Manual ultrasonics

- Dye penetrant inspection

- Phased array ultrasonic testing

- Time of flight diffraction

Our team of experienced NDT engineers can also provide comprehensive ad-hoc support for the following inspection methods:

- Visual testing

- Magnetic particle inspection

- Eddy current inspection

- Alternating current field measurement

- Acoustic emission