Reliability, Availability and Maintainability Study (RAMS)

RAMS refers to Reliability, Availability and Maintainability Study which is a decision making tool used to identify how to increase the availability of the system, and thus increase the overall profit as well as reducing the life cycle costs.

Concept of Reliability

Reliability is defined as the fraction or percentage of time that an item is available to respond to a demand placed upon it. Various techniques such as Reliability Block Diagrams (RBDs) and Fault Tree Analysis (FTA) can be used to determine the Reliability.

Concept Of Availability

Availability is defined as a fraction or percentage of time that an item has not failed and thus available for a demand. Based on this particular approach, unavailability can be defined as a fraction or percentage of time that an item has failed.

Concept Of Maintenance

Active and Reactive maintenance programs are required in order to ensure the reliability of equipment and thus the reliability and availability of Safety Instrumented Functions.

Objectives of a RAM Analysis

Our expert team of consultants have been providing Reliability, Availability and Maintainability studies and analysis for various industries. The main objectives of a RAM analysis is for it to be used as a decision making tool to increase the availability of the system, and thus increase the overall profit as well as reducing the life cycle costs (inclusive of the cost of maintenance, lost production, operating, etc.). RAM analysis can be carried out on systems and facilities of different types and sizes in various industries ranging from oil and gas, water and waste water treatment, nuclear, process, manufacturing and many more.

FAQ

RAM analysis can be applied at various stages of the life cycle.

Pre-FEED (i.e. design conceptualisation) – RAM analysis can be used to compare various design options that are being considered through quantification of the production output of each option.

Conducting a RAM analysis at this stage, whilst the design is still being finalised is known to reduce the cost and schedule impact on the project than if conducted at a later stage.

FEED – At the FEED stage, critical equipment’s are identified which could cause significant production losses. A RAM analysis would normally be conducted on these critical equipment’s in order to optimise the equipment configuration and identify the requirements of any further spares or equipment redundancies in order to optimise the availability of the system.

Detailed Engineering – At the detailed engineering stage it is likely that the design is frozen with minimal changes. A RAM study at this point would allow the client to identify performance targets that must be met by the equipment, which can be used as part of the equipment design specification during procurement.

Process Operation – Whilst the process is in operation, conducting a RAM study using the data of the as-built facility can bring the benefit of identifying unreliable equipment which are leading to production losses.

As a minimum, the following information would be required in order to conduct the workshop:

– P&ID’s

– Cause and Effects Diagrams

– Facilities Design

– Operating Data and Procedures

– Heat and Material balances

– Equipment Rating and Data Sheets

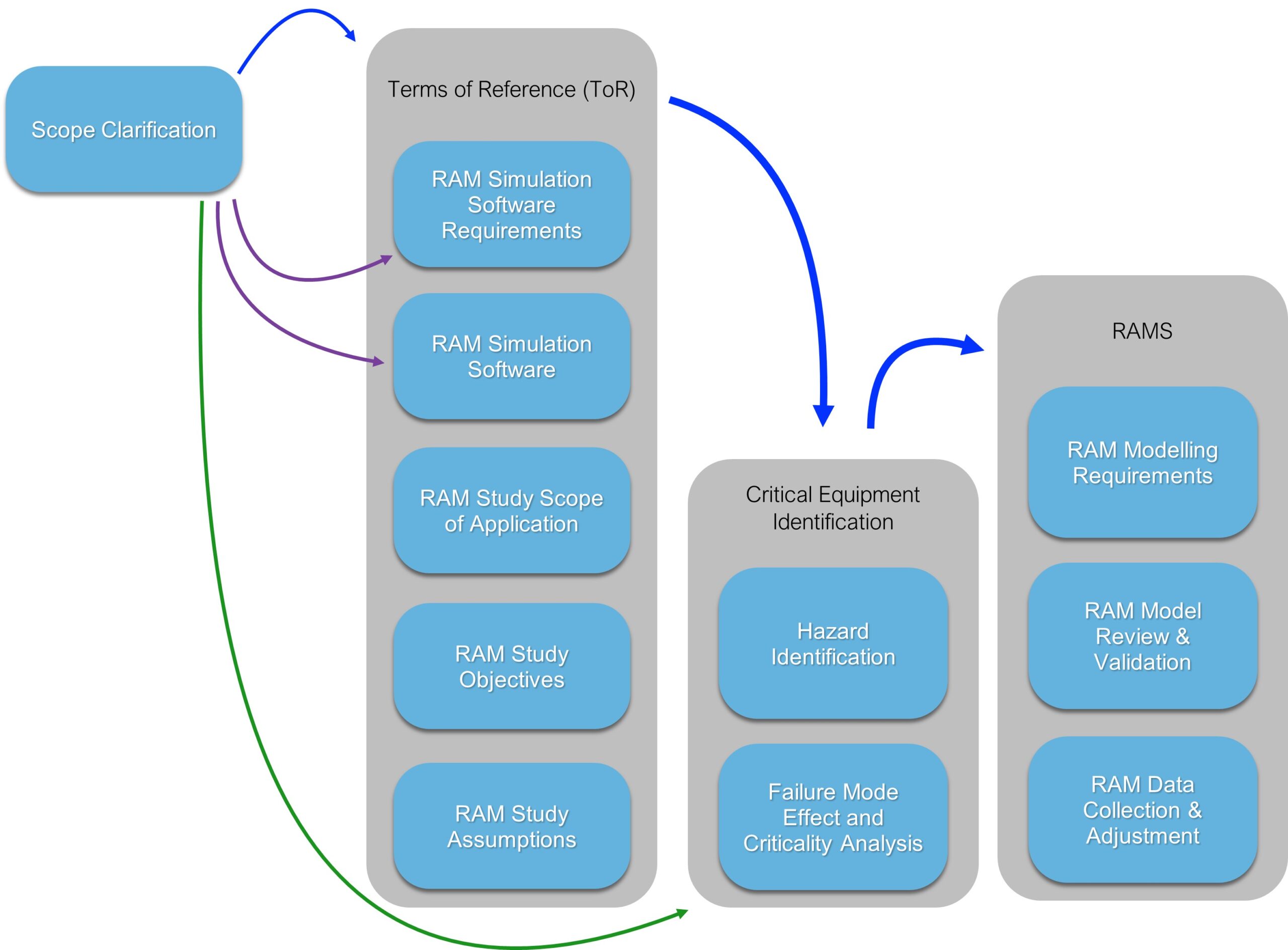

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

On award of the study ES will issue a project ToR, which will highlight the assumptions that shall be made in the study, along with data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the assumptions and data sources, ES will prepare a RAM analysis report describing the facility, the scope of work, a detailed methodology, the failure rate data utilised, the results of the analysis and any recommendations based on the results in order to improve the availability. Recommendations can include, but not limited to:

– Storing of spare parts,

– Adding equipment in order to provide redundancy, etc.

Based on the results of the analysis, if required, ES can also conduct a Cost Benefit Analysis (CBA).

ES are a globally renowned provider of RAM analysis studies with significant experiences predominantly within the Oil & Gas Industry. ES have their own in-house RAM analysis tool built based on our vast experiences of conducting RAM studies. For more information, or to discuss your needs, please contact us using the form below or email [email protected]