Control Hazard and Operability (CHAZOP)

Control Hazard and Operability Study, formally known as a CHAZOP, is a procedure for carrying out the safety and reliability analysis of existing or planned control and computer systems.

This analytical methodology comprehensively addresses all potential causes of failure, including hardware, software, human factors, cyber security and external factors such as power failure. They highlight areas where unwarranted assumptions have been made, training and management are weak, and single points of failure exist that can lead to a process shutdown.

CHAZOP Objectives

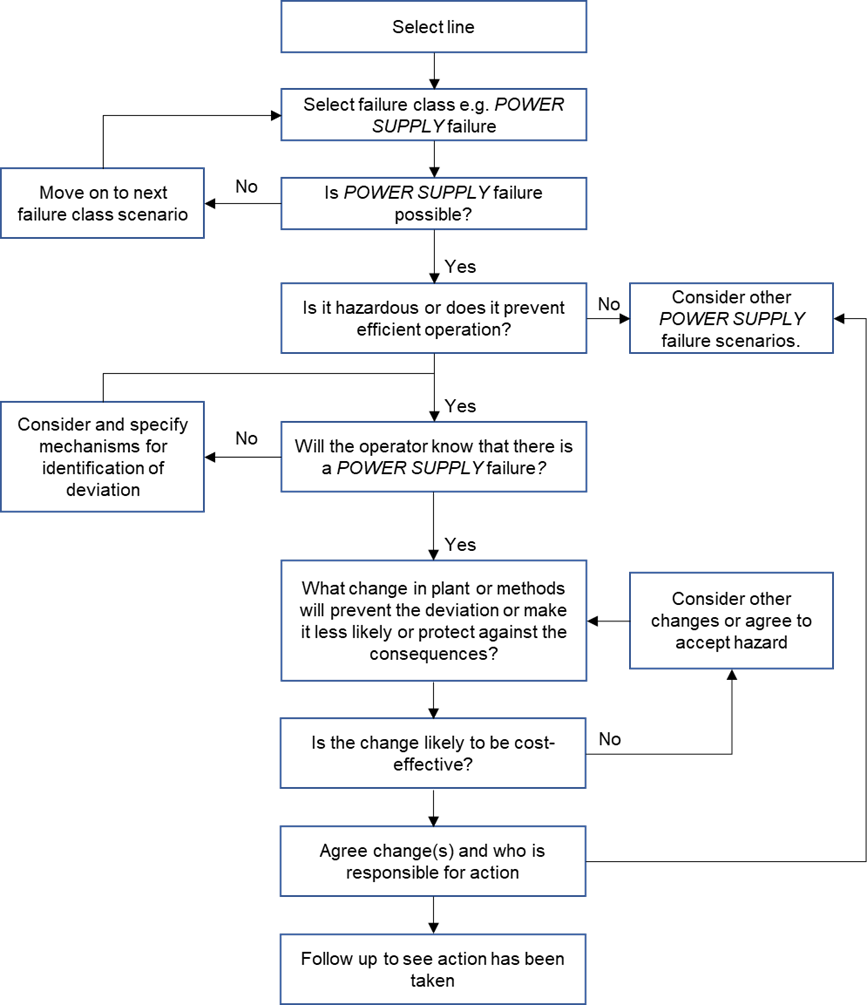

The purpose of a CHAZOP is to find possible causes of process upset due to control system failure. A CHAZOP can be performed using the ‘What-If’ procedure.

The output of this study is a detailed list of all possible consequences of a control system failure, optionally including the assessment of the frequencies and severities of the outcomes. This can give a direct indication of whether tolerable risk targets are met; if they are not met, further action will be needed. CHAZOP also provides a wealth of other information including:

- a list of potentially critical failure cases needing more detailed study using Layer of Protection Analysis (LOPA)

- a set of recommendations for design changes or further study

- a means of determining critical points of failure

- a list of key safeguards (protective measures) on which the safety of the process is highly dependent

- the frequency of demand on safeguards that provide a layer of protection against the consequences of control system failures

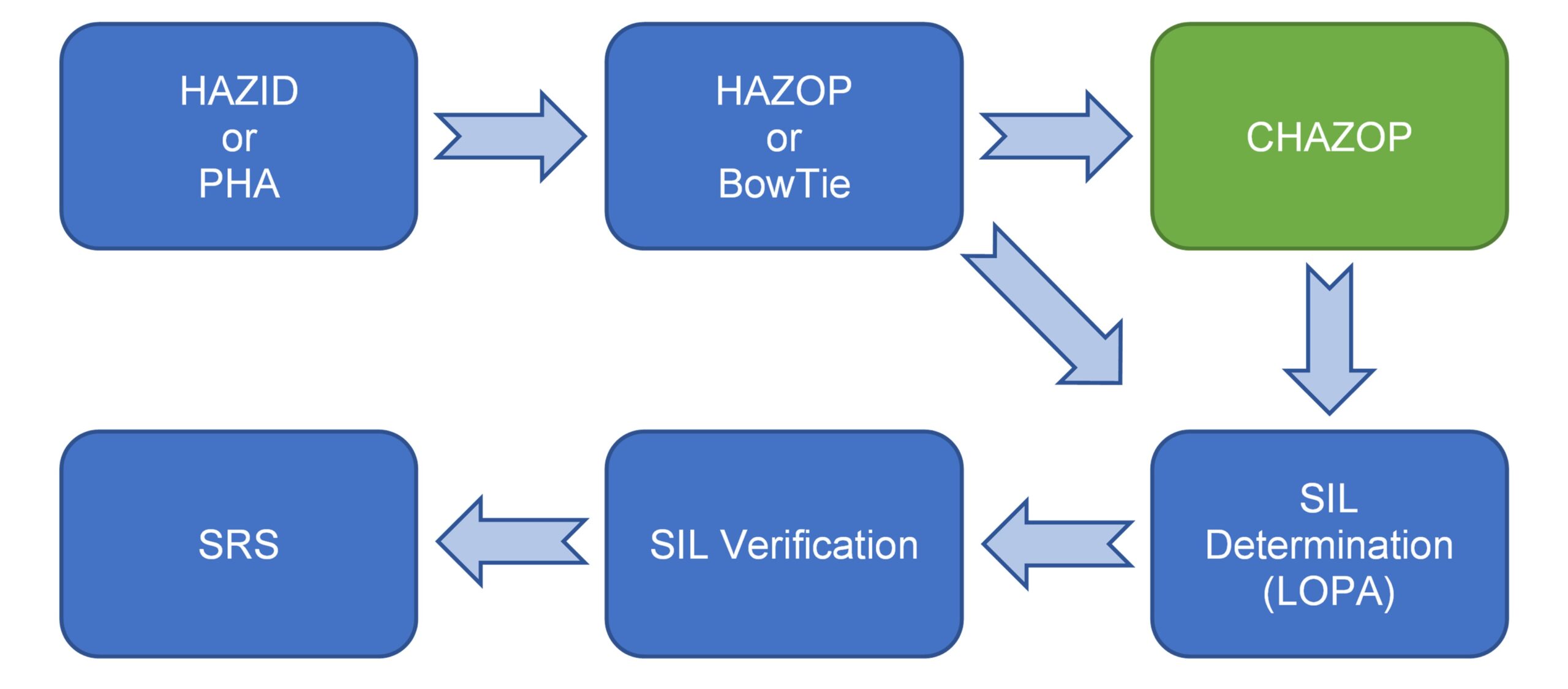

One of the key inputs to a CHAZOP study is a Hazard and Operability (HAZOP) report for the process equipment under consideration. A CHAZOP should therefore come after a HAZOP in the project timeline. Furthermore, a CHAZOP yields information needed for the Safety Integrity Level (SIL) determination study, so a CHAZOP should be performed before the SIL determination is conducted.

FAQ

As a minimum, the following information would be required in order to conduct the workshop:

– Existing PHA / HAZOP report with pertinent actions (if available)

– Safety Instrumented System (SIS) loop diagrams or block diagrams

– Control network diagrams

– Data sheets, operating and service manuals and wiring diagrams for all hardware

– Cause and Effects Diagrams

– Power feed data and architecture

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

Most of the information needed relates to electrical, control and data systems, including both system hardware and software and networks. Process engineers and operators may be required from time to time, but not necessarily on a full-time basis. Third party information may be needed if there are critical data connections to outside. Package vendor guidance may be required when studying package Programmable Logic Solvers (PLCs). Depending on the project requirements, any additional personnel that may be required to attend the workshop, will be highlighted within the ToR accordingly.

On award of the study ES will issue a project ToR, which will highlight the assumptions that shall be made in the study, along with the workshop details, methodology and data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, ES will facilitate the CHAZOP study through a workshop providing the facilitator and scribe. Once the workshop has been conducted ES will prepare a CHAZOP report describing the facility, the scope of work, a detailed methodology, the CHAZOP worksheets, a summary of the CHAZOP actions and any recommendations based on the discussions during the workshop. ES highly recommends that following on from the CHAZOP study, a SIL Classification or SIL Determination analysis is conducted since a CHAZOP yields pertinent information needed for the SIL study.

ES are a globally renowned facilitators of CHAZOP studies having conducted many hours of CHAZOP studies, with a team of TUV Rheinland certified Functional Safety Engineers available for facilitation. For more information, or to discuss your needs for conducting a CHAZOP study, please contact us using the form below or email [email protected]