Pre Start-up Safety Review (PSSR)

A Pre Start-up Safety Review is a final check prior to starting up the facility, to confirm that the following Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) / Environmental Protection Agency (EPA) Risk Management Program (RMP) requirements are met:

- The process or facility has been built as designed.

- All required documentation and procedures is in place.

- Employee training and competence is complete.

- All action items from the Process Hazard Analysis (PHA) for the activity have been resolved.

PSSR Aproach

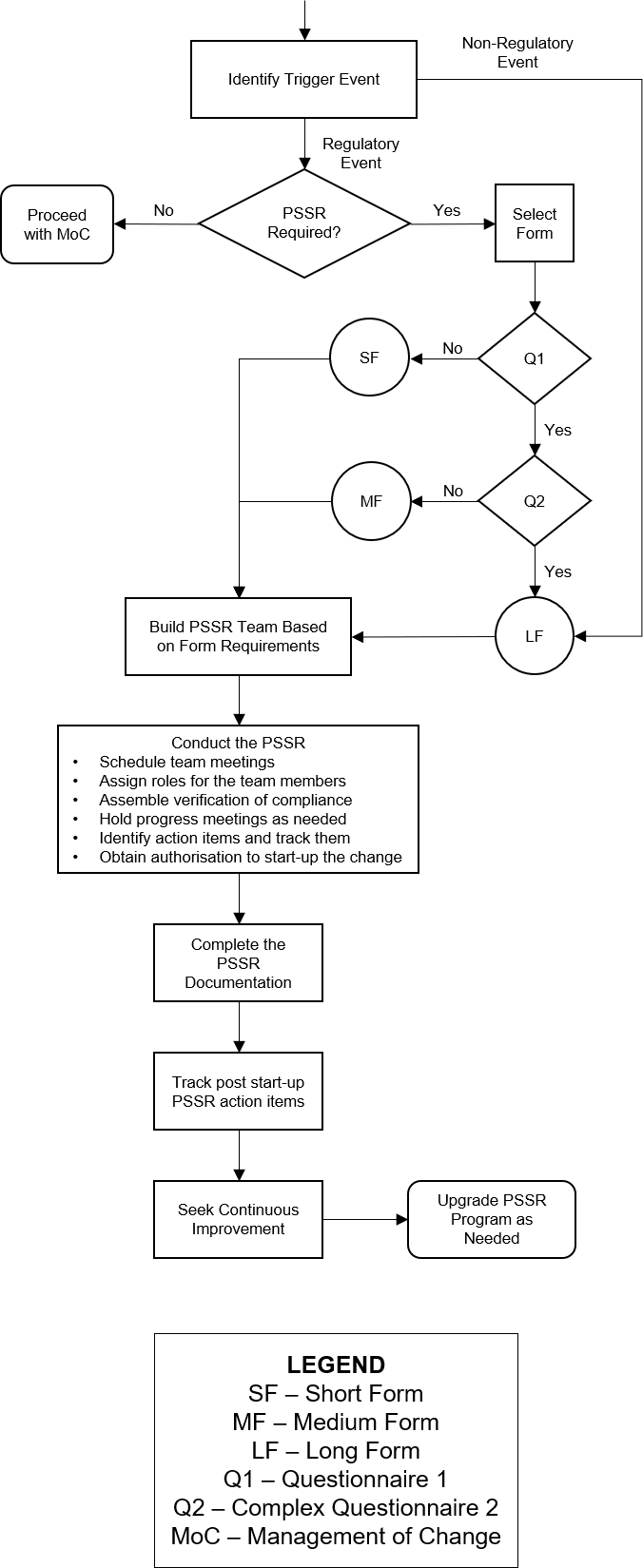

Referring to the methodology flowchart opposite, there are seven basic steps considered for conducting a PSSR:

Step 1: Identify trigger events and determine if a PSSR is required

The basis for the PSSR procedure should begin with the identification of the triggering event. That is, identifying if the event in question details any changes being made to an existing process, any new facilities being added to a process or facility, or any non- Process Safety Management (PSM) covered triggered event designated by the facility as benefiting from the review:

- Non-trigger events cover capital projects, start-up post Emergency Shutdown (ESD), routine maintenance, etc.

- Trigger events cover Management of Change (MoC) raised events.

Step 2: Determine the type of PSSR to perform

The basis for the PSSR form selection depends solely on the complexity of the review in question. If the change is straightforward, well understood, and can be signed off with use of minimal PSSR resources yet still be effective; the Short Form will be most suitable.

Nevertheless, if the change is more complex and would benefit from a deeper engineering and process safety related check to provide an additional level of protection – a technique proven to improve safety performance; the Medium or Long form will be more desirable. The purpose of this split is so that a PSSR can be less resource intensive but still provide the required end result. ES have developed a qualitative risk based questionnaire, Q1 and Q2, to evaluate the onerous requirements of the PSSR.

Step 3: Build the PSSR team

The PSSR team size is determined based upon the technical aspects of the change, the nature of the risk and the complexity of the review. The team should consist of a sufficient number of multi-disciplinary experts who have proficiency in some applicable area of expertise relevant to the plant, process or equipment concerned.

Step 4: Conduct the PSSR

The following items are to be administered throughout the PSSR process:

- Assignment of roles for team members.

- Collection of required documentation for the review.

- Regular PSSR team meetings and field inspections as required by the company of the change.

- Identify which items are applicable and which are not.

- Identify and track all relevant action items and verify that all applicable sections of the selected PSSR form have been considered.

- Identify issues that must be corrected before start-up and issues that must be corrected after start-up.

The above approach may differ depending upon the type and complexity of the review.

Step 5: Complete PSSR documentation

This involves a formal completion of the hardcopy form or electronic documentation showing that the PSSR is complete, a final physical review of the facility has been undertaken, indicated action items have been addressed and any post-startup items are tracked.

Step 6: Track any post start-up PSSR action items

All action items, required to be completed after start-up, have been successfully tracked and documented ready for completion.

Step 7: Seek continuous improvements to PSSR programme

Lessons learned, and recommendations are to be advised for continual PSSR improvements.

FAQ

Every facility has its own approach to maintaining plant information that may help a PSSR team complete its assigned tasks, and every PSSR may have slightly different needs in regard to the information necessary for a thorough review. However, as a minimum, the following information would be required in order to conduct the workshop:

– PHA, HAZID and HAZOP reports with actions list, tracking and closure

– Operation and maintenance procedures

– Process safety information

– Safe work practices and procedures (PTW, hot works, etc.)

– Site risk assessments (EERA, ERP, QRA, EIA, etc.)

– P&ID’s and PFDs

– Shutdown and ESD philosophy

– Site acceptance testing documentation, evidence and records

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

The PSSR team size is determined based upon the technical aspects of the change, the nature of the risk and the complexity of the review. In any case, the team should consist of a sufficient number of multi-disciplinary process experts who may or may not have intimate familiarity with the process or modifications. As a minimum, the following personnel would be required in order to conduct the workshop:

– MoC initiator

– Process and process safety specialists

– Technical consultants or equipment specialists

– Engineers across various disciplines (civil, electrical, structural, etc.)

– Management representative

– Operations and maintenance representatives

Based on the project requirements, additional personnel may be required to attend the workshop, which will be highlighted within the ToR.

On award of the study ES will issue a project ToR or PSSR plan, which will highlight the assumptions that shall be made in the study, along with data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, ES will facilitate the PSSR study through a workshop providing the facilitator and scribe. Once the workshop has been conducted, ES will prepare a PSSR report describing the facility, the PSSR scope, a detailed methodology, the PSSR worksheets, a summary of the PSSR conclusions and the recommendations based on the discussions during the workshop.

ES are globally renowned facilitators of PSSR studies having conducted many hours of PSSR studies, with a team of TUV Rheinland certified Functional Safety Engineers available for facilitation. For more information, or to discuss your needs for conducting a PSSR study, please contact us using the form below or email [email protected]