Process Hazard Analysis

Process Hazard Assessment (PHA) is a set of organised and systematic assessments of the potential hazards associated with an industrial process. A PHA can provide information intended to assist in making decisions for improving safety and reducing the consequences of unwanted or unplanned releases of hazardous chemicals. A PHA is often directed towards analysing potential causes and consequences of undesirable events and focuses on equipment, instrumentation, utilities, human actions, and external factors that might impact the process.

PHA methods are qualitative in nature. The selection of a methodology to use depends on a number of factors, including the complexity of the process, the length of time a process has been in operation and if a PHA has been conducted on the process before, and if the process is unique, or industrially common.

Methods of Process Hazard Assessment

There are a variety of methodologies that can be used to conduct a PHA, including but not limited to:

– Checklist;

– What if?;

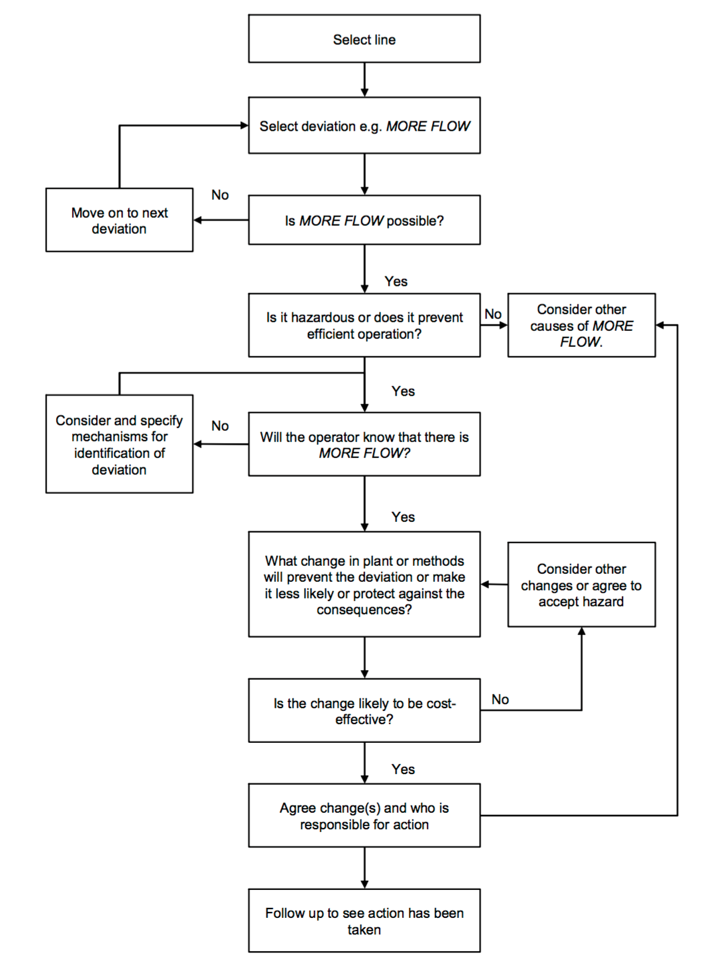

– Hazard and Operability Study (HAZOP);

– Hazard Identification (HAZID);

– Failure Mode and Effects Analysis (FMEA).

Risk Ranking in Process Hazard Assessment

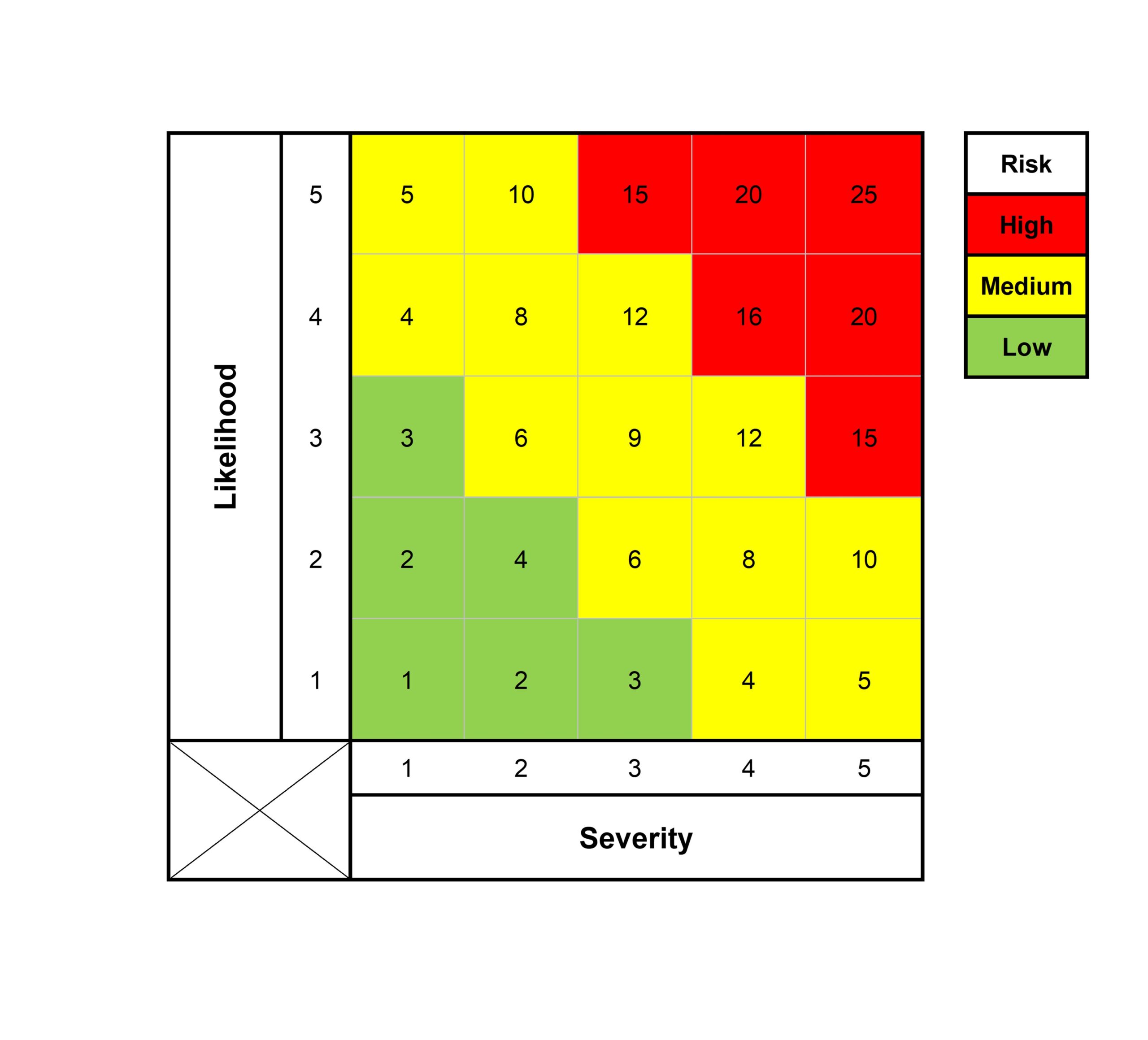

Depending on company requirements, or the selected method of Process Hazard Assessment, Risk Ranking of identified hazards is typically carried out. Risk Ranking is the process of qualitatively determining the risk as a combination of severity and likelihood with the help of a standard risk matrix. Based on this combination, risk prioritisation is carried out.

The severity should be determined for consequences related to Health & Safety, Environmental, Financial, Asset Damage and Reputation. The likelihood is the event frequency per year which should be based on the company, as well as on historical databases. Many different kinds of risk matrices are used across various industries, with the most common one being a 5X5 Matrix.

For true Risk Ranking, it is appropriate to introduce the concept of As Low As Reasonably Practicable (ALARP). ALARP is the level to which risk should be controlled and compares the risk with the sacrifice involved in further reducing it. If the costs of further controls are high, but they will only reduce the risk a small amount, then they may be grossly disproportionate. ALARP has been reached. However, if further controls can make significant risk reductions, or are cheap and easy to implement, they will need to be introduced to reach ALARP. This notion is widely recognised and is a common feature in many PHA studies.

FAQ

As a minimum, the following information would be required in order to conduct the workshop:

– Existing PHA / HAZOP report (if available)

– P&ID’s

– Cause and Effects Diagrams

– Facilities Design

– Operating Data and Procedures

– Maintenance Data and Procedures

– Interlock List

– Equipment Data Sheet

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

As a minimum, the following personnel would be required in order to conduct the workshop:

– Process Engineer

– Controls and Instrumentation Engineer

– Process Safety Engineer

– Maintenance representative

– Operations representative

Based on the project requirements, additional personnel may be required to attend the workshop, which will be highlighted within the ToR.

On award of the study ES will issue a project ToR, which will highlight the assumptions that shall be made in the study, along with the workshop details, methodology and data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, ES will facilitate the PHA study through a workshop providing the facilitator and scribe. Once the workshop has been conducted ES will prepare a PHA report describing the facility, the scope of work, a detailed methodology, the PHA worksheets, a summary of the PHA actions and any recommendations based on the discussions during the workshop. ES highly recommends that following on from the PHA study, a SIL Classification or SIL Determination analysis is conducted in order to determine the SIL requirements for the SIF’s identified during the workshop.

ES are a globally renowned facilitators of Process Hazard Assessment studies having facilitated 100’s of hours of PHA studies, with a team of TUV Rheinland certified Functional Safety Engineers available for facilitation. ES can facilitate PHA studies using various methodologies such as HAZOP’s, HAZID’s, What If’s, etc. For more information, or to discuss your needs for conducting a PHA study, please contact us using the form below or email [email protected]