Simultaneous Operations (SIMOP)

Simultaneous Operations (SIMOP) occur when two or more activities or process operations are being coordinated in the same location at the same time. This can often bring about an undesired event (or series of events) which could result in a Major Accident Hazard (MAH), Environmental Impact (EI) or loss of Assets. SIMOP can also impact schedules, commercial aspects and business reputation.

SIMOP usually involves multiple company interfaces (owners, contractors, vendors, etc.) and a wide range of routine and non-routine daily disciplines. The purpose of the SIMOP study is designed to identify:

- Schedule clashes (time and space).

- Physical clashes (vessel to vessel and / or facility collisions).

- Failure Impacts (Loss Of Containment (LOC), etc.).

- Climatic conditions (weather, currents, etc.).

- Contractual Clashes (3rd party interfaces).

- Territorial Clashes (Operations within the defined safe zones).

- Any other scenarios or conflicts identified.

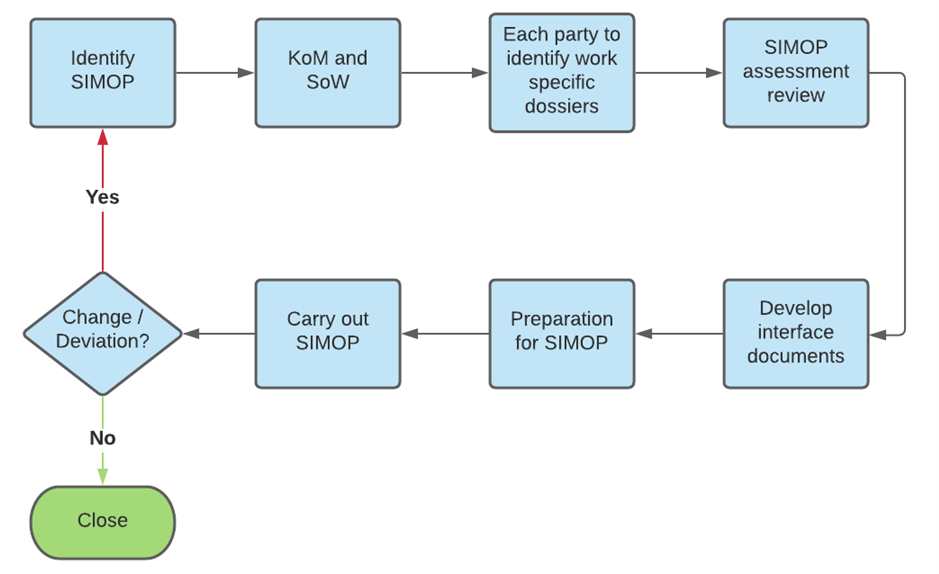

The whole SIMOP process, from identification to implementation, is illustrated below.

SIMOP Process

The idea of the SIMOP study is to reduce or eliminate all risks to an As Low As Reasonably Practicable (ALARP) condition by:

- Identifying all constraints and hazards associated with all proposed activities.

- Listing all corresponding mitigation measures.

- Defining the Safe Working Zones (SWZs) and agree boundaries.

- Discussing agreements with each SIMOP party on work specific dossier content.

FAQ

As a minimum, the following information would be required in order to conduct the workshop:

– Basis of Design

– Existing HAZID, HAZOP and QRA reports

– Environmental impact assessment

– Emergency response planning and plans

– Facility design layout / plant layout drawings

– P&ID’s and PFDs

– List of hazardous substances and inventories impacted by the project

– Contractors and operations permit to work system and hazard management program

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

The SIMOP project team should be comprised of appropriately experienced members of the workforce who can participate in hazard identification and risk assessments for the SIMOP, as well as identification of suitable procedures to be used and any new documentation that may be required for the project. It is therefore mandatory that participation of a multidisciplinary group of personnel are present. As a minimum, the following personnel from each concerned party would be required in order to conduct the workshop:

– Site HSE manager

– Process and process safety specialists

– Construction manager

– Commissioning manager

– Operations representatives

Based on the project requirements, additional personnel may be required to attend the workshop, which will be highlighted within the ToR.

On award of the study ES will issue a project ToR or SIMOP plan, which will highlight the assumptions that shall be made in the study, along with data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, ES will facilitate the SIMOP study through a workshop providing the facilitator and scribe. Once the workshop has been conducted, ES will prepare a SIMOP report describing the facility, the SIMOP scope, a detailed methodology, the SIMOP worksheets, a summary of the SIMOP conclusions and the recommendations based on the discussions during the workshop.

ES are globally renowned facilitators of SIMOP studies having conducted many hours of SIMOP studies, with a team of TUV Rheinland certified Functional Safety Engineers available for facilitation. For more information, or to discuss your needs for conducting a SIMOP study, please contact us using the form below or email [email protected]